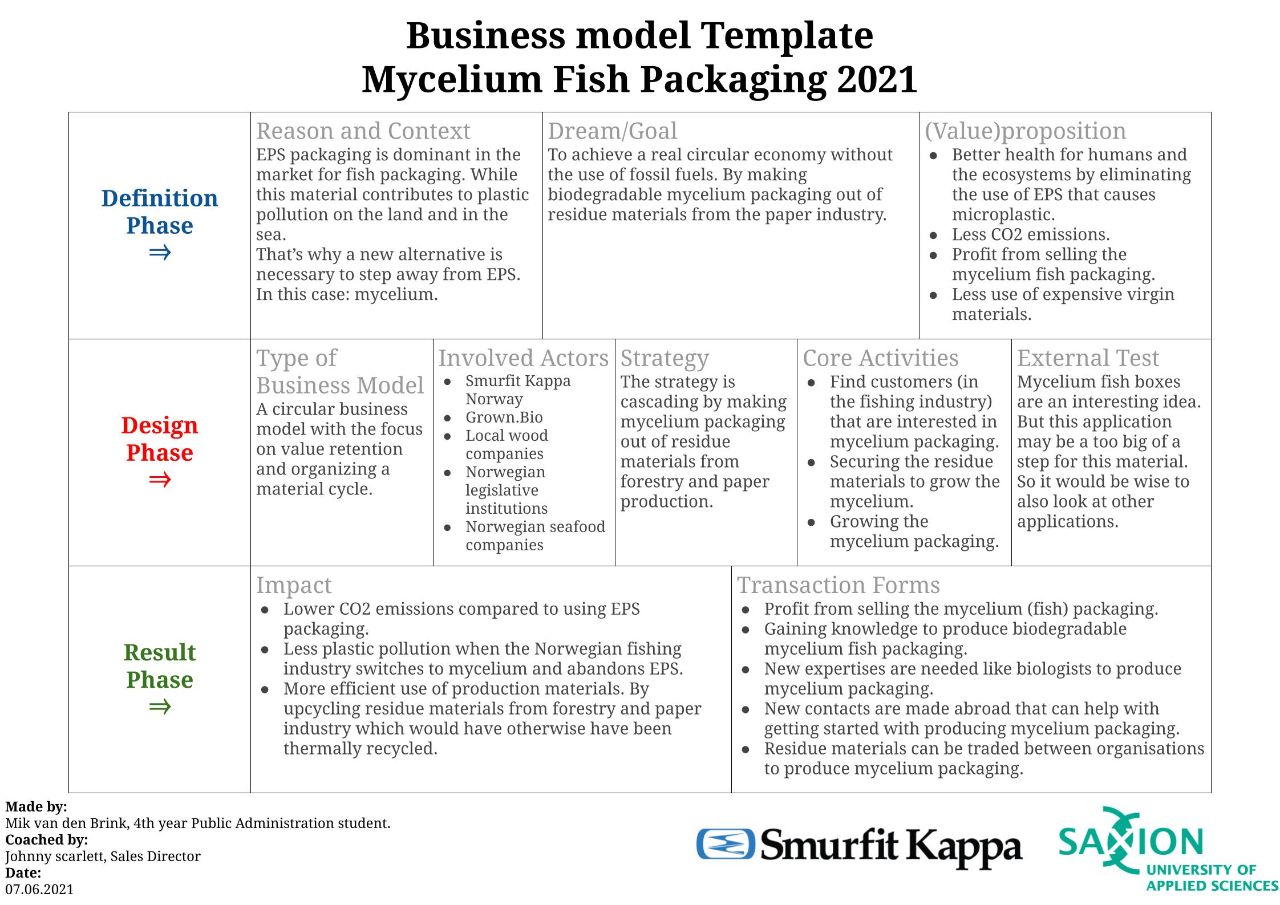

As a student of Public Administration / Government Management I am interested in working on social issues. Combating plastic pollution in the environment is one of those challenges that I would like to contribute to now and in the future. For example, during my graduation assignment at Smurfit Kappa Norway, I worked on finding an alternative to expanded polystyrene (EPS) fish boxes. Since this type of plastic packaging contributes to maritime pollution with all its consequences.

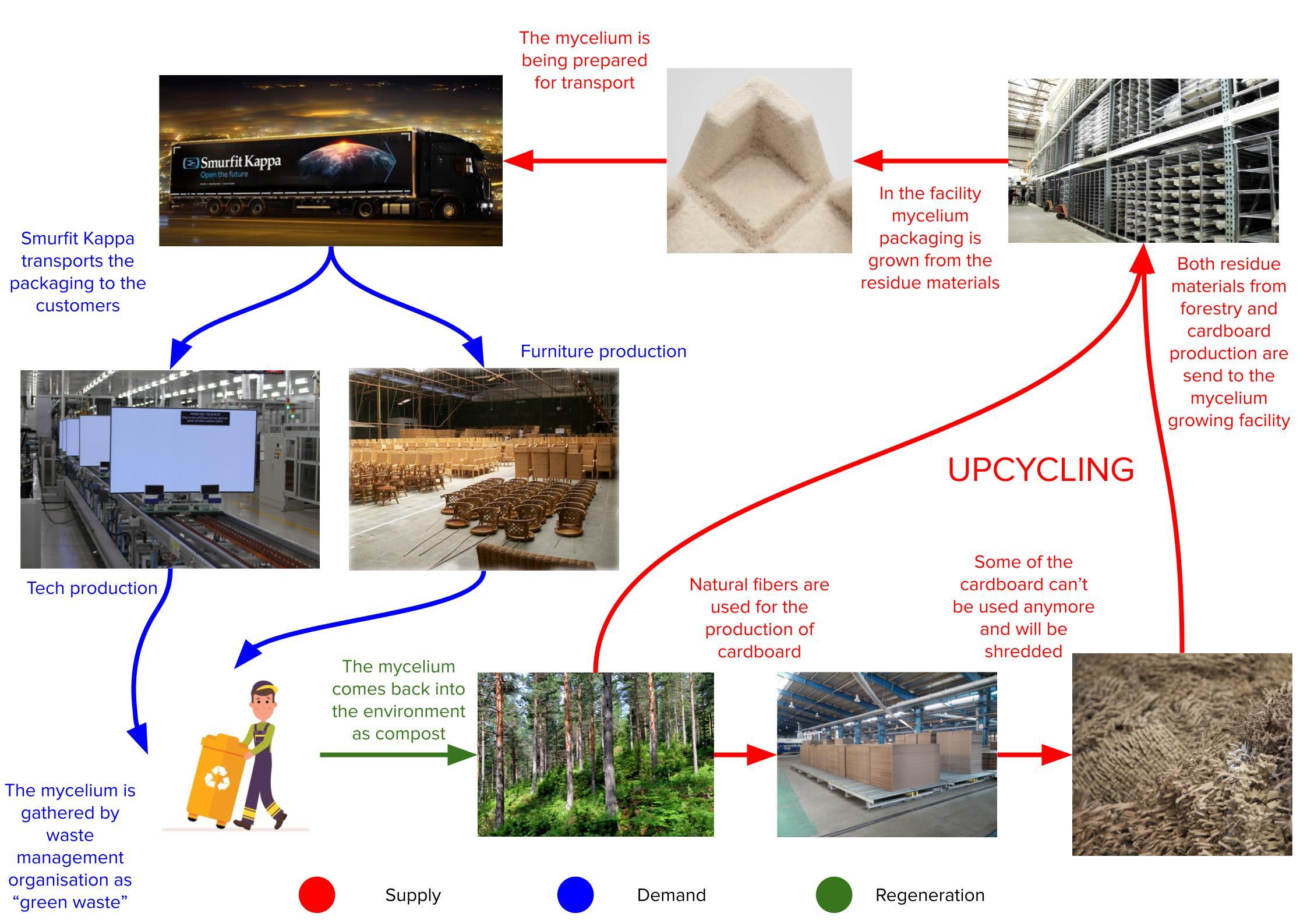

With the Smurfit Kappa project group (consisting of myself and two Smurfit Kappa employees) we looked into the possibility of using mycelium (a material made from hyphae and biomass such as hemp). Because mycelium as a biodegradable material has similar properties compared to EPS. But because this material is still relatively unknown in Norway, we asked for help from a start-up company in the Netherlands, Grown.Bio, which is engaged in, among other things, making mycelium packaging materials. During the collaboration between Grown.Bio and Smurfit Kappa, we developed a mycelium fish packaging prototype that will be further tested in Norway. The possibilities for using the paper residual materials within Smurfit Kappa for growing mycelium packaging materials for the furniture industry are also being explored.

My role in this entire project was mainly in process management. Where I made sure the project was started and the development process kept going. The development process with all those involved also shaped my graduation assignment, resulting in the business model. I also used the Business model template of Jan Jonker and Niels Faber to set up and structure my business model.

[1] Jonker, J., & Faber, N. (2020). Duurzaam organiseren (1st ed.). Amsterdam, Nederland: Boom uitgevers.